NEMA enclosures are made to shield electrical components from their surroundings. NEMA enclosures can safeguard people and things in the surrounding area while protecting the equipment. Read More…

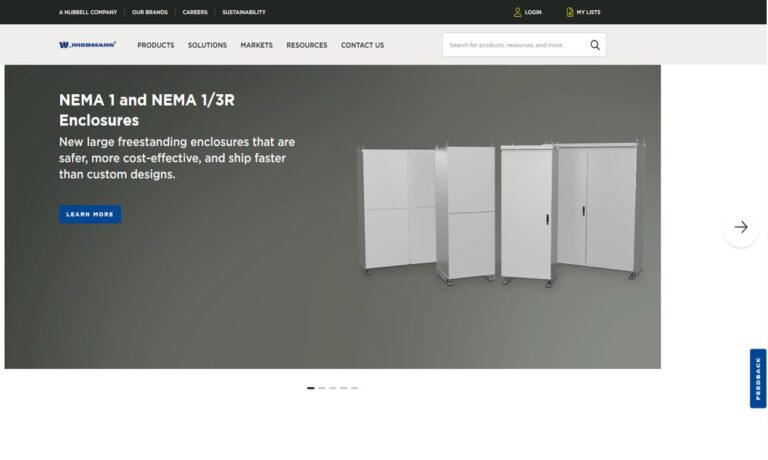

At Hubbell Wiegmann, we specialize in designing and manufacturing high-quality electronic enclosures that protect and support a wide range of industrial and commercial systems. We bring decades of engineering expertise to every product we create, ensuring that our enclosures meet rigorous performance standards while adapting to the evolving needs of our customers.

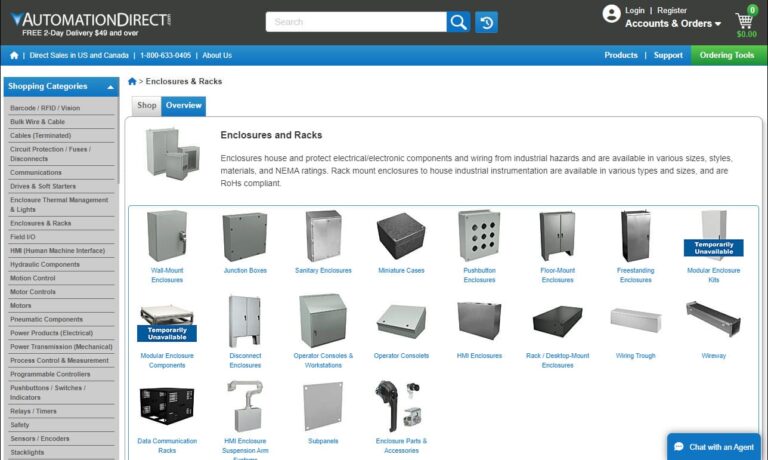

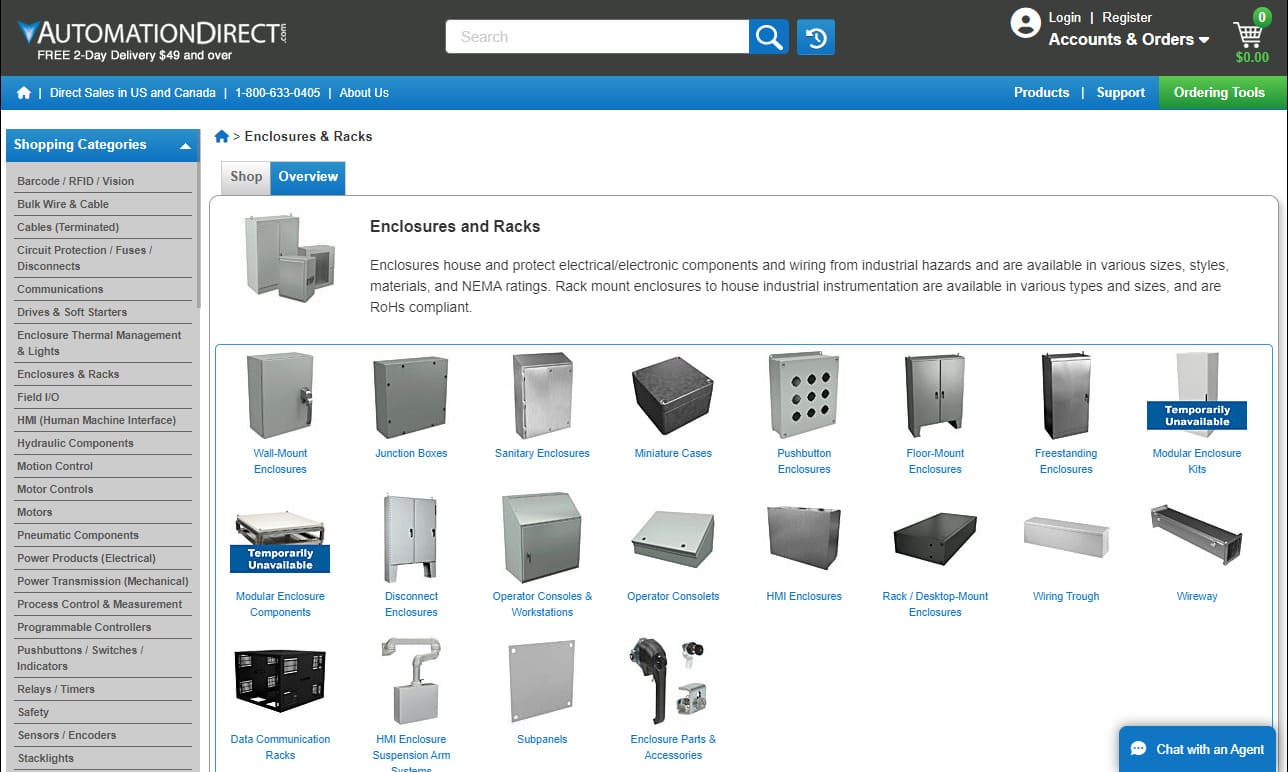

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

At Ometek Inc., we specialize in designing and manufacturing high-quality industrial electronic enclosures for a wide range of applications. Our team of skilled engineers and technicians has years of experience in the industry, and we are committed to delivering the most reliable and durable enclosures to our customers.

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

At Bison ProFab, we specialize in designing and manufacturing high-quality electronic enclosures that deliver superior protection in the most demanding environments. We take pride in our ability to engineer enclosures that meet rigorous industry standards while adapting to the specific needs of our customers across a broad range of applications.

More NEMA Enclosure Manufacturers

NEMA enclosures, developed by the National Electrical Manufacturers Association (NEMA), play a critical role in safeguarding sensitive electrical and electronic equipment across a wide range of industrial, commercial, and hazardous environments. These high-quality electrical enclosures are designed to provide essential protection against environmental hazards, unauthorized access, and physical damage, while ensuring compliance with industry safety standards and local regulations.

Key Applications and Use Cases for NEMA Enclosures

NEMA-rated enclosures are engineered to address specific safety and operational requirements. Some specific situations where NEMA enclosures are employed include:

- Industrial and manufacturing facilities where personnel interact with volatile chemicals or hazardous materials

- Environments prone to explosions caused by electrical arcing, sparking, or combustible dust (such as oil refineries, paint shops, and chemical processing plants)

- Preventing worker injuries and equipment failures due to accidental contact with exposed electrical components

- Securing sensitive electronic, communications, and control equipment from unauthorized access or tampering

- Outdoor installations subject to harsh weather, dust, and water ingress (construction sites, utilities, telecommunications, and renewable energy applications)

- Facilities requiring compliance with OSHA, NEC, and other electrical safety regulations

Wondering which NEMA enclosure is right for your electrical project? Explore the full range of NEMA enclosure types, features, and industry-specific applications below to make an informed decision.

Types of NEMA Enclosures and Their Protective Features

Choosing the appropriate NEMA enclosure type is essential for maximizing equipment lifespan, reducing maintenance costs, and ensuring uninterrupted operations. The NEMA rating system categorizes enclosures based on their ability to protect against environmental hazards such as dust, water, chemicals, and corrosion. Below are the most common NEMA enclosure types, their applications, and key protective features:

NEMA Type 1 Enclosure – General Purpose Indoor Protection

NEMA Type 1 enclosures are best suited for general indoor use in non-hazardous environments. These basic electrical enclosures provide a cost-effective solution for protecting electrical controls, wiring, and instrumentation from accidental contact, falling dirt, and light debris. They are commonly used in offices, retail spaces, and light commercial applications where minimal environmental threats are present.

- Key Features: Basic protection against solid objects; prevents accidental human contact with energized electrical parts

- Common Uses: Circuit breaker panels, control panels, PLC cabinets, and instrumentation enclosures in indoor settings

NEMA Type 2 Enclosure – Drip-Resistant Indoor Protection

Designed for indoor environments with occasional exposure to moisture, NEMA Type 2 enclosures offer all the protection of Type 1, plus resistance to dripping and light splashing of non-corrosive liquids. Typically equipped with drip shields, these enclosures are ideal for locations with high humidity or condensation, such as laundry rooms, utility closets, or spaces near HVAC equipment.

- Key Features: Drip-tight construction; protection from dripping water and light splashes; maintains electrical safety in damp areas

- Common Uses: Enclosures for control systems, relays, and power distribution in damp indoor locations

NEMA Type 3 Enclosure / Type 3X Enclosure – Weather-Resistant Outdoor and Indoor Protection

NEMA Type 3 enclosures are engineered to withstand harsh outdoor and indoor environments, providing protection against rain, snow, sleet, wind-blown dust, and falling debris. These weatherproof electrical enclosures are suitable for exposed installations such as rooftop HVAC units, outdoor electrical panels, and industrial machinery. The Type 3X variant adds enhanced corrosion resistance, making it ideal for coastal, marine, or chemical plant environments where saltwater or corrosive agents may be present.

- Key Features: Weather-resistant, protects against rain, sleet, snow, windblown dust, and external ice formation; 3X offers corrosion resistance

- Common Uses: Outdoor control panels, telecommunications equipment, junction boxes, and traffic signal cabinets

NEMA Type 4 Enclosure / Type 4X Enclosure – Watertight and Corrosion-Resistant Protection

NEMA Type 4 enclosures are designed for both indoor and outdoor use, offering watertight performance even under direct hose-down conditions. They provide comprehensive protection against rain, snow, sleet, dust, and splashing water, making them suitable for washdown areas, food processing plants, and industrial sites requiring high levels of hygiene. Type 4X enclosures further enhance corrosion resistance, utilizing materials like stainless steel or reinforced fiberglass to withstand aggressive chemicals and saltwater exposure.

- Key Features: Watertight, protects against hose-directed water, splashing, dust, and external ice; 4X has added corrosion protection

- Common Uses: Food & beverage processing, chemical plants, outdoor marine applications, water treatment facilities, and pharmaceutical manufacturing

NEMA Type 5 Enclosure – Dust-Tight Industrial Protection

NEMA Type 5 enclosures offer superior protection against airborne dust, fibers, lint, and debris, making them a top choice for manufacturing facilities, woodworking shops, and textile mills. These dust-tight electrical boxes are engineered to prevent the ingress of particulate contaminants, ensuring the reliability of sensitive control systems and instrumentation in high-dust environments.

- Key Features: Sealed against airborne dust and particles, protects internal components from settling debris and light moisture

- Common Uses: Enclosures for motor controls, process automation, and sensors in dusty industrial settings

NEMA Type 6 Enclosure – Submersible and Waterproof Solutions

NEMA Type 6 enclosures are built for environments where temporary, limited-depth submersion is possible. These waterproof and submersible electrical enclosures are essential for applications such as underground utility vaults, irrigation systems, and outdoor lighting controls exposed to flooding or heavy rain. They offer robust protection against water ingress from hose-directed spray and short-term submersion, while resisting damage from ice buildup.

- Key Features: Submersible, watertight, withstands hose-directed water and temporary submersion; not harmed by ice or sleet

- Common Uses: Underground electrical boxes, marine equipment housings, and outdoor power distribution units

NEMA Type 7 Enclosure – Explosion-Proof Indoor Protection for Hazardous Locations

NEMA Type 7 enclosures are specifically engineered for use in hazardous indoor locations classified as Class I, Groups A, B, C, and D under the National Electrical Code (NEC). Often referred to as explosion-proof enclosures, they are designed to contain internal explosions and prevent the propagation of flames or hazardous gases outside the enclosure. These rugged electrical enclosures are essential for chemical processing, petroleum refineries, and any facility handling flammable gases or vapors.

- Key Features: Explosion containment, prevents ignition of hazardous atmospheres; meets NFPA 70 and NEC standards

- Common Uses: Hazardous area lighting, electrical controls, instrumentation, and motor starters in explosive environments

NEMA Type 8 Enclosure – Explosion-Proof Solutions for Indoor and Outdoor Hazardous Locations

NEMA Type 8 enclosures extend explosion-proof protection to both indoor and outdoor hazardous areas. They are certified for Class I, Groups A, B, C, and D, and are constructed to prevent ignition of volatile substances such as acetylene, hydrogen, gasoline, propane, and other flammable chemicals. These enclosures are frequently utilized in oil & gas operations, chemical plants, distilleries, and grain silos where both weatherproofing and explosion containment are required.

- Key Features: Explosion-proof, weather-resistant, suitable for hazardous and outdoor locations; contains internal explosions

- Common Uses: Outdoor hazardous area controls, gas detection systems, and petrochemical facility instrumentation

Additional NEMA Enclosure Types and Specialized Ratings

Beyond the most common NEMA enclosure ratings, there are several specialized types designed for unique operational requirements. For example, NEMA Type 6P enclosures offer extended submersion protection for continuous underwater use, while NEMA Types 12, 13, and 250 address requirements such as oil-tightness, corrosion resistance, and protection from circulating splashes or sprayed water. When choosing an enclosure, always verify compatibility with local codes and the specific demands of your installation environment.

Materials and Construction Options for NEMA Enclosures

The choice of enclosure material is a crucial consideration for performance, longevity, and total cost of ownership. Common materials include:

- Stainless Steel: Offers superior corrosion resistance and durability for outdoor, marine, and food processing environments.

- Carbon Steel: Provides robust protection at a lower cost, ideal for indoor industrial use where corrosion is not a primary concern.

- Aluminum: Lightweight and corrosion-resistant, suitable for outdoor and transportation applications.

- Fiberglass Reinforced Polyester (FRP): Non-conductive, chemical-resistant, and lightweight, suitable for highly corrosive or non-metallic requirements.

- Polycarbonate and Thermoplastics: Used for lightweight, impact-resistant, and non-corrosive enclosures in indoor and select outdoor settings.

Need help choosing the right enclosure material for your environment? Compare the benefits and drawbacks of each material type, and consult with a NEMA enclosure supplier for expert advice tailored to your project.

Benefits of NEMA Enclosures in Industrial and Commercial Settings

Integrating NEMA-rated enclosures into your electrical infrastructure delivers a wide range of operational and safety advantages:

- Enhanced Equipment Protection: Safeguards sensitive electrical devices from moisture, dust, corrosive agents, and mechanical impacts.

- Safety Compliance: Meets OSHA, NEC, and local code requirements for electrical safety, reducing liability and ensuring regulatory approval.

- Reduced Downtime: Minimizes the risk of equipment failure and production interruptions due to environmental hazards.

- Extended Equipment Lifespan: Reduces maintenance and replacement costs by shielding components from harsh conditions.

- Security and Access Control: Prevents unauthorized tampering or vandalism of critical control systems and instrumentation.

- Versatility: Wide selection of sizes, mounting options, and customization possibilities to fit unique project requirements.

Looking to improve workplace safety, reduce maintenance costs, or streamline code compliance? Discover how investing in the right NEMA enclosure can optimize your facility’s performance and protect your assets.

Decision Factors: How to Select the Best NEMA Enclosure for Your Application

Choosing the optimal NEMA enclosure involves evaluating several technical and environmental factors:

- Environmental Hazards: Assess exposure to water, dust, chemicals, temperature extremes, and potential impacts.

- Location: Determine whether the enclosure will be used indoors, outdoors, or in a hazardous (classified) area.

- Material Requirements: Consider corrosion resistance, weight, strength, and chemical compatibility.

- Size and Mounting: Ensure sufficient space for equipment, wiring, and ventilation, with appropriate mounting accessories.

- Certification Standards: Confirm NEMA ratings, third-party certifications (such as UL or CSA), and code compliance.

- Customization Options: Evaluate the need for modifications such as cutouts, paint finishes, locking mechanisms, and climate control features (heaters, fans, filters).

Not sure where to start? Try searching for “best NEMA enclosure for outdoor use,” “explosion-proof electrical enclosure suppliers,” or “NEMA 4X stainless steel enclosure pricing” to compare solutions, pricing, and supplier reviews.

Frequently Asked Questions About NEMA Enclosures

- What is the difference between NEMA and IP ratings? NEMA and IP (Ingress Protection) ratings both describe enclosure protection levels, but NEMA ratings are more common in North America and often include additional performance criteria such as corrosion and gasket integrity. IP ratings (used internationally) primarily address dust and water ingress.

- Can NEMA enclosures be customized? Yes, most NEMA enclosure manufacturers offer custom fabrication, including custom sizes, cutouts, ventilation, colors, and mounting options to meet unique project requirements.

- How do I know which NEMA rating I need? Identify the specific environmental hazards present at your installation location, and select an enclosure with a NEMA rating that meets or exceeds those conditions. Consult with a qualified enclosure supplier for guidance.

- Are NEMA enclosures suitable for outdoor use? Many NEMA types (such as 3, 3X, 4, 4X, 6, and 6P) are designed for outdoor use. Always verify the enclosure’s rating before installation.

Choosing the Correct NEMA Enclosure Supplier

To ensure you achieve the most productive outcome when purchasing a NEMA enclosure from a NEMA enclosure supplier, it is important to compare several companies using our directory of NEMA enclosure suppliers. Each NEMA enclosure supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each NEMA enclosure business website using our proprietary website previewer for a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple NEMA enclosure businesses with the same form.

Searching for a reliable NEMA enclosure manufacturer or distributor near you? Use our supplier directory to compare NEMA enclosure suppliers by location, specialty, certifications, and customer reviews. Request multiple quotes to get the best value and lead time for your project.

Start Your NEMA Enclosure Project Today

Ready to protect your critical electrical systems with a high-quality, code-compliant NEMA enclosure? Browse our comprehensive supplier directory, request custom quotes, and leverage our resources to make an informed purchasing decision. Whether you need a weatherproof outdoor electrical box, explosion-proof control panel, or corrosion-resistant stainless steel enclosure, our network of trusted NEMA enclosure manufacturers can deliver the solution you need.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

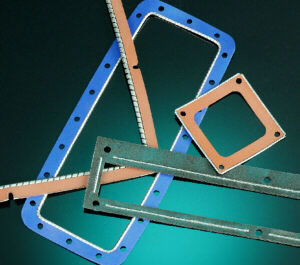

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services