An electric casing is a cabinet for mounting switches, knobs, and displays on electric or electronic equipment, as well as protecting the equipment’s contents from the elements and preventing electrical shock to users. The sole component of the apparatus that users can see is the enclosure. It might have been created with aesthetics in mind in addition to its functional requirements. Read More…

Since 1975, we have been doing precision sheet metal fabrication. Our expertise is in high production, high quality ISO 9000 Certified service. Dedicated manufacturing with on-time delivery. Electronic enclosures, chassis, frames, bracketry to extremely complex weldments and components.

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

EMCOR® Enclosures is a modular enclosure manufacturer and makes related component items as well. Our electronic equipment racks and enclosures feature an extensive selection of rack heights, widths, depths, and styles that target your specific design requirements. A variety of external and internal accessories are available to complete your design. Modified or custom designs are also available....

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

Buckeye ShapeForm manufactures electronic enclosures and electrical enclosures that take your company to the next level! Different types include desktop, handheld and rackmount. We will help you with the entire process, from selection, design and customization to finishing.

More Electrical Cabinet Manufacturers

The performance and features of electrical equipment enclosures in hazardous locations, such as petrochemical factories or coal mines, may be governed by regulations. An electronic package may place a lot of demand on an enclosure, including requirements for heat transfer, radio frequency interference protection, and electrical discharge protection, in addition to functional, aesthetically pleasing, and financially viable requirements.

Materials

Solid polymers or metals like stainless steel, steel, or aluminum are typically used to create electrical enclosures. Electrical enclosures fabricated from steel might be coated. While handmade or small production models typically have standardized enclosures, mass-produced equipment has a customized enclosure. ABS is only used indoors for plastic enclosures, not in hostile situations. Where tougher cabinets are needed, fiberglass, polycarbonate, and glass-reinforced boxes are utilized; they may also have a gasket to keep out dust and moisture.

Metal cabinets might be conductive enough to insulate enclosed electronics from electromagnetic interference and bond electrical safety. For metallic conduit systems to be correctly joined, non-metallic enclosures can need additional installation stages. Although plastics like polycarbonate, polystyrene, and acrylonitrile butadiene styrene are alternatives, electrical cabinets are normally built of aluminum.

A body stiffener may be needed for tall cabinets for strength. Typically, cold-rolled steel is used for the cabinets, and the seams are continually welded. The knockout handles and doors are applied following a finish, like a powder coating. Depending on the use, accessories like shelves and drawers are optional but may be useful.

Polycarbonate Plastic

Enclosures made of polycarbonate plastic offer great impact resistance and are typically cheaper than metal enclosures. Additionally, polycarbonate is adaptable and suited for indoor and outdoor uses. Due to its cost and durability, it's a good option for other non-metallic cabinet materials like PVC (polyvinyl chloride).

Polycarbonate enclosures are frequently utilized in portable electronic and electrical instruments connected to the IT industry due to their comparatively inexpensive cost. They're also a popular option for electrical uses that use non-metallic cables. However, they can also be used with metallic cable if a ground wire is provided and correctly placed.

ABS Plastic

While ABS (acrylonitrile butadiene styrene) plastic doesn't offer the same robustness as polycarbonate, it is still sturdy with high resistance to shocks and heat. In addition, ABS is often one of the more economical enclosure material options. As a result, it's one of the most widely used kinds of electrical enclosures for interior applications that need only the most minimal security.

Aluminum

Comparatively speaking, aluminum cabinets are more expensive than plastic enclosures. However, these cabinets provide some significant advantages of their own. Aluminum is a very strong material that can tolerate high temperatures and is appropriate for outdoor and indoor boxes. Aluminum alloys also provide inherent EMI/RFI shielding to reduce interference and are very resistant to corrosion. Since a metal enclosure is typically required to ground the conduit, metallic enclosing materials like aluminum are particularly crucial for operations that use metallic conduit or metal-sheathed wire.

Stainless Steel

Stainless steel enclosures have benefits and drawbacks, just like most enclosure materials. Stainless steel is a heavy material typically more costly than other enclosure materials, despite being fire-resistant and functioning well in moist situations. Nevertheless, it is still a preferred material for metallic boxes because of its great durability and appealing look. Like aluminum, it can serve as a grounding agent for metallic conduits and metal-sheathed cables.

Carbon Steel

Enclosures made of carbon steel are sturdy and affordable. However, they should not be utilized in coastal areas because of their high corrosion susceptibility since the salt in the atmosphere can quickly erode the enclosure unless a protective coating powder is added.

Applications

These cabinets can be seen on public streets or partially covered by plants in the park, for example. Electrical cabinets are typically located on the lower floors or utility rooms of structures and dwellings. They are frequently used in every industry to safeguard exposed connections, operation switches, and circuit breakers. In addition to withstanding earthquakes and tornadoes, outdoor enclosures can be certified to endure debris, rain, sleet, snow, and wind and ice development on the enclosures outside. Indoor cabinets also need to be durable and are typically dust and waterproof.

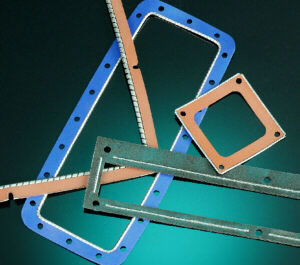

For instance, the lines are systematically cleaned daily in a dairy or meat processing facility. Any moisture penetrating the enclosure will breed germs and corrode the enclosure and the electrical parts. In addition, the cabinets may come into contact with caustic or toxic elements in chemical industries that other cabinets could not handle. Electromagnetic interference, which damages electrical equipment due to electromagnetic waves or conduction from an outside source, is another danger from which electrical cabinets shield their contents. There are special coatings that can protect a cabinet's contents from EMI or RFI.

Choosing the Proper Electrical Cabinet Manufacturer

To ensure the most positive outcome when purchasing an electrical cabinet from an electrical cabinet manufacturer, it is important to compare several companies using our directory of electrical cabinet manufacturers. Each electrical cabinet manufacturer has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each electrical cabinet business website using our proprietary website previewer to learn what each company specializes in. Then, use our simple RFQ form to contact multiple electrical cabinet businesses with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services