Electrical enclosures protect electronic instruments and equipment from accidental contamination, interference, and touch. These enclosures’ contents, which frequently contain delicate electrical circuitry components, must be shielded from airborne contaminants like dust and liquids like water. Additionally, accidental contact with this circuitry could harm people and harm the machinery itself. Electromagnetic interference (EMI) can interfere with the operation of many electronics by disrupting their circuitry without a suitable shield. Read More…

Since 1975, we have been doing precision sheet metal fabrication. Our expertise is in high production, high quality ISO 9000 Certified service. Dedicated manufacturing with on-time delivery. Electronic enclosures, chassis, frames, bracketry to extremely complex weldments and components.

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

EMCOR® Enclosures is a modular enclosure manufacturer and makes related component items as well. Our electronic equipment racks and enclosures feature an extensive selection of rack heights, widths, depths, and styles that target your specific design requirements. A variety of external and internal accessories are available to complete your design. Modified or custom designs are also available....

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

Buckeye ShapeForm manufactures electronic enclosures and electrical enclosures that take your company to the next level! Different types include desktop, handheld and rackmount. We will help you with the entire process, from selection, design and customization to finishing.

More Electrical Enclosure Manufacturers

Design of Electrical Enclosures

Electrical enclosures are essential components in the protection and organization of sensitive electrical and electronic equipment. Typically manufactured from durable materials such as aluminum, stainless steel, or high-grade plastic, these enclosures are frequently rectangular but can be custom-engineered into a variety of shapes and sizes, depending on application needs. Their dimensions range from compact enclosures, just a few square inches in size for devices like LED flashlight housings, to expansive, room-sized walk-in enclosures designed for industrial control systems or large-scale electrical distribution.

Modern electrical enclosure design focuses on balancing robust protection, ease of access, and integration with a wide variety of equipment. For instance, some enclosures—such as electrical cabinets—feature snap-together clamshell construction, while others incorporate doors or removable panels for convenient maintenance and equipment upgrades. Stainless steel and aluminum enclosures can be formed into rounded or custom-contoured shapes to accommodate disc-shaped meters, gauges, or specialized electronic components.

There are several types of electrical enclosure configurations to meet the requirements of different applications. Typical formats include:

- Portable enclosures: Compact, lightweight, and designed for handheld or mobile use.

- Desktop enclosures: Used for benchtop control panels, laboratory instruments, or testing stations.

- Display enclosures: Feature clear panels or windows for screen visibility and touch interface.

- Wall-mounted enclosures: Offer flexible installation options for industrial, commercial, or residential environments.

- Cabinet enclosures: Large, floor-standing units for housing extensive electrical panels, PLCs, motor controls, or automation systems.

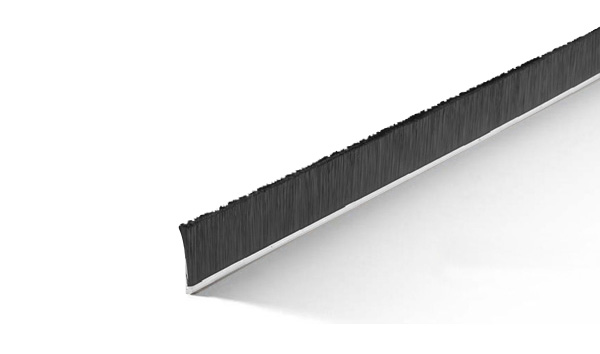

When evaluating custom electrical enclosures or off-the-shelf models, the design complexity can vary widely. Some enclosures are constructed from simple, hollow, lidded aluminum boxes that are wall-mounted, while others feature molded plastic forms with intricate knockouts, ventilation slots, and internal mounting structures to secure specific components. Flanges and gaskets are often incorporated to ensure a weatherproof and dust-tight seal, which is critical for outdoor or harsh industrial settings.

Aluminum enclosures are frequently manufactured using extrusion—a process where metal bars are forced through precision dies to create long, uniform profiles. This method provides excellent structural integrity and allows for custom lengths and cross-sections. Stainless steel enclosures are typically cold-rolled and welded to form durable boxes or cabinet structures that resist corrosion and mechanical damage. In contrast, plastic enclosures offer advantages such as lightweight construction, electrical insulation, and resistance to many chemicals. For heavy-duty or hazardous applications, metal—especially stainless steel or powder-coated steel—is usually preferred due to its superior durability and grounding capabilities.

Are you wondering what type of enclosure best fits your project? Contact an electrical enclosure manufacturer today to discuss your specific requirements, including size, material, ingress protection ratings, and custom features such as cutouts, latches, or locking mechanisms.

Key Applications and Use Cases for Electrical Enclosures

Electrical enclosures are utilized in a broad range of industries and settings, providing critical protection and organizational benefits wherever electrical systems are deployed. Common applications include:

- Industrial automation: Protecting programmable logic controllers (PLCs), variable frequency drives (VFDs), and other control electronics from dust, moisture, and accidental contact.

- Commercial and institutional facilities: Housing electrical distribution panels, circuit breakers, and surge protectors in secure, accessible locations.

- Telecommunications: Safeguarding networking equipment, fiber optics, and communication modules from weather and vandalism.

- Renewable energy: Enclosing inverters, battery management systems, and monitoring electronics for solar, wind, or battery storage installations.

- Transportation and infrastructure: Providing weatherproof protection for traffic control systems, railway signaling equipment, and roadside electronics.

- Marine and offshore: Ensuring electrical safety and corrosion resistance in shipboard, dockside, and offshore oil or gas environments.

- Hazardous locations: Preventing explosions and fires by containing electrical sparks or arcs in classified areas such as chemical plants or refineries.

Looking to choose the right electrical enclosure for your application? Consider the specific environmental hazards, physical size requirements, and regulatory standards relevant to your industry. Consult with a supplier who can guide you through the selection process for optimal safety and performance.

Types of Electrical Enclosures

There are various types of electrical enclosures available, each designed to meet unique environmental challenges and regulatory standards. Understanding the different types—and their corresponding NEMA ratings or IP ratings—is essential when specifying enclosures for critical equipment. Below are some of the most common types:

NEMA 6 Enclosures

NEMA 6 enclosures are engineered for both indoor and outdoor use, particularly in scenarios where short-term, occasional submersion in water is possible. These watertight and dust-tight enclosures are frequently used in industries such as marine transportation, electric vehicles, agricultural facilities, and wastewater treatment plants. A NEMA 6 enclosure offers robust protection against hazardous contact with energized parts, as well as defense against moisture, falling dirt, ice formation, and water ingress during temporary submersion.

Typical features of NEMA 6 enclosures include:

- Sealed gaskets and reinforced seams for water resistance

- Corrosion-resistant finishes for outdoor or marine environments

- Availability in various materials, including powder-coated steel, stainless steel, or impact-resistant plastics

Are you comparing NEMA 6 to other enclosure ratings? Explore our NEMA ratings guide to understand which enclosure type is best for your needs.

NEMA 6P Enclosures

NEMA 6P enclosures extend the protection offered by NEMA 6 by allowing for prolonged submersion in water and providing enhanced corrosion resistance. These waterproof and submersible enclosures are the preferred choice for the most challenging and extreme environments, including underground mining operations, offshore oil rigs, marine installations, and areas routinely exposed to chemical spray or harsh cleaning processes.

Key benefits of NEMA 6P enclosures:

- Long-term submersion in water without compromising the safety or function of internal components

- Superior corrosion resistance, ideal for chemical, food processing, and saltwater applications

- Protection from dust, dirt, and other airborne contaminants

- Compliance with stringent safety and reliability standards

Need help selecting a waterproof enclosure for harsh environments? Contact us or use our enclosure finder tool to match your requirements with the right NEMA or IP-rated enclosure.

NEMA 7 Enclosures

NEMA 7 enclosures are specifically engineered for hazardous indoor locations classified as Class I, Division 1, Groups A, B, C, or D under the NFPA 70 National Electrical Code. These areas contain flammable gases or vapors that could ignite and cause explosions. NEMA 7 enclosures are also known as explosion-proof enclosures because they are designed to contain internal explosions, preventing the propagation of flames or hot gases to the surrounding environment. This makes them indispensable in chemical processing plants, oil and gas refineries, and industrial manufacturing facilities where safety is paramount.

Features and applications of NEMA 7 enclosures:

- Thick, heavy-duty steel or aluminum construction for blast containment

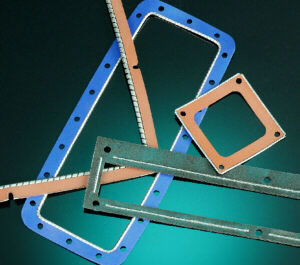

- Precision-machined joints and flanges to prevent vapor transmission

- Integral mounting provisions for electrical controls, relays, or instrumentation

- Compliance with OSHA and NEC requirements for hazardous locations

Want to learn more about explosion-proof enclosures and hazardous location ratings? Read our guide or speak with an enclosure specialist for detailed recommendations.

NEMA 12 Enclosures

NEMA 12 enclosures are ideal for indoor environments where protection from dust, dirt, dripping non-corrosive liquids, and falling debris is required. Commonly used in manufacturing plants, warehouses, and commercial facilities, these enclosures offer greater protection than basic NEMA 1 or NEMA 2 types. However, they are not intended for outdoor use or for exposure to corrosive chemicals. NEMA 12 enclosures keep sensitive electrical equipment—such as automation controls, relays, and electronic sensors—operating reliably by preventing the ingress of airborne particulates and accidental contact with fluids.

Advantages of NEMA 12 enclosures include:

- Resistant to dust, lint, fibers, and dripping water

- Sturdy construction with optional lockable doors for security

- Available in wall-mounted, floor-standing, or modular designs

- Suitable for general industrial control, machine tool, or commercial distribution panels

Are you evaluating NEMA 12 versus NEMA 4 or NEMA 4X enclosures for your facility? Compare features and benefits in our NEMA enclosure comparison chart.

Ingress Protection (IP) Ratings and International Standards

In addition to NEMA ratings, electrical enclosures are often evaluated using Ingress Protection (IP) ratings as defined by the international standard IEC 60529. IP ratings provide a two-digit code that signifies the level of protection against solid objects (such as dust) and liquids (such as water). For example, an IP66 enclosure is fully dust-tight and protected against powerful water jets, while an IP68 enclosure can withstand prolonged submersion.

Key IP ratings for electrical enclosures:

- IP54: Dust-protected and splash-resistant

- IP65: Dust-tight and protected against water jets

- IP66: Complete protection from dust and strong water jets

- IP67: Dust-tight and protected against immersion up to 1 meter

- IP68: Dust-tight and suitable for long-term submersion

Benefits of High-Quality Electrical Enclosures

Investing in the right electrical enclosure yields a range of operational, safety, and compliance benefits. Key advantages include:

- Equipment protection: Shields sensitive electronics from dust, moisture, impacts, and corrosive agents, extending service life.

- Safety compliance: Helps meet OSHA, NEC, UL, and IEC standards for electrical safety and hazard mitigation.

- Operational reliability: Reduces downtime due to equipment failure by maintaining a controlled environment for components.

- Security: Prevents unauthorized access, tampering, or vandalism with locking panels and robust construction.

- Customizability: Allows for tailored solutions with custom cutouts, color matching, branding, and accessory integration.

- Ease of installation and maintenance: Features modular designs, quick-access panels, and options for cable management.

Looking for advice on maximizing the lifespan of your electrical equipment? Discover our maintenance tips or request a consultation with an enclosure specialist to match your environment and budget.

Factors to Consider When Selecting Electrical Enclosures

Choosing the optimal electrical enclosure involves balancing several critical factors. Consider the following when researching or requesting quotes:

- Material selection: Evaluate whether stainless steel, aluminum, carbon steel, fiberglass, or polycarbonate plastic is best for your environment.

- Environmental hazards: Assess exposure to water, chemicals, dust, UV, and temperature extremes.

- Size and form factor: Ensure adequate space for equipment, wiring, and future expansion.

- Ingress protection: Match NEMA or IP ratings to your specific risk profile (e.g., waterproof, dustproof, explosion-proof).

- Mounting options: Wall, pole, floor, or custom mounting requirements.

- Access and security: Consider locking mechanisms, hinged doors, or quick-release panels as needed.

- Compliance and certification: Confirm that the enclosure meets UL, CSA, CE, or other relevant standards.

- Customization needs: Factor in requirements for custom cutouts, integrated displays, or special finishes.

Have a specific enclosure challenge or application in mind? Ask our experts about custom electrical enclosure solutions and get recommendations tailored to your project.

Choosing the Right Electrical Enclosure Supplier

Selecting a reputable electrical enclosure supplier is crucial for ensuring your project’s success. To achieve the best outcome when sourcing electrical enclosures, we recommend using our comprehensive directory of trusted manufacturers and suppliers. Each supplier profile highlights their unique areas of expertise, material capabilities, and industry certifications, making it easy to compare options and connect with the most qualified companies for your needs.

Steps to find your ideal electrical enclosure supplier:

- Browse our directory of verified electrical enclosure manufacturers by location, specialty, and materials offered.

- Review business profile pages to evaluate experience, past projects, and customer testimonials.

- Use our patented website previewer to get an in-depth look at each supplier’s range of products and customization options.

- Fill out our easy-to-use RFQ (Request for Quote) form to contact multiple suppliers at once and receive competitive pricing.

- Discuss your application, technical specifications, and delivery timelines directly with shortlisted suppliers to ensure a perfect fit.

Thinking about a custom enclosure, or need help navigating certifications and compliance? Request a consultation through our contact form and let us connect you with experienced electrical enclosure manufacturers who can deliver the quality, performance, and support your project demands.

Frequently Asked Questions about Electrical Enclosures

- What is the difference between NEMA and IP ratings?

NEMA (National Electrical Manufacturers Association) and IP (Ingress Protection) ratings are both systems for classifying the environmental protection offered by electrical enclosures. NEMA ratings are more widely used in North America and often include additional criteria such as corrosion resistance or explosion protection. IP ratings are internationally recognized and focus solely on protection against solids and liquids. Learn more about NEMA vs IP ratings. - How do I choose the right material for my enclosure?

The best material depends on your operating environment. Stainless steel provides excellent corrosion resistance and durability; aluminum is lightweight and dissipates heat well; plastic is non-conductive and cost-effective. Consider factors such as exposure to chemicals, temperature, and UV rays when making your choice. - Can electrical enclosures be customized for my application?

Yes, most manufacturers offer custom enclosures with options for size, shape, cutouts, colors, mounting provisions, and integrated accessories. Explore custom electrical enclosure solutions. - Do I need a weatherproof or waterproof enclosure?

If your equipment will be exposed to rain, washdowns, or immersion, select an enclosure with an adequate NEMA (e.g., 4X, 6, or 6P) or IP (e.g., IP65, IP66, or IP68) rating. Consider the specific hazards of your environment to ensure the best protection. - What industries use specialized electrical enclosures?

Nearly every sector relies on electrical enclosures, including manufacturing, automation, food processing, pharmaceuticals, transportation, energy, telecommunications, and hazardous locations such as oil & gas or chemical processing. - How do I maintain my electrical enclosure?

Regular inspection, cleaning, and checking the integrity of gaskets and seals can help prolong enclosure life and maintain protection levels. Choose enclosures with easy-access panels for simplified maintenance.

Take the Next Step: Find Your Ideal Electrical Enclosure

Ready to source the best electrical enclosure for your project? Whether you need a standard NEMA-rated box, a custom-fabricated stainless steel cabinet, or a weatherproof solution for harsh outdoor conditions, our network of leading electrical enclosure manufacturers has you covered. Contact us today for expert advice, detailed product information, and fast, competitive quotes tailored to your application.

Still have questions? Explore our comprehensive resource library for in-depth guides, technical articles, and the latest news on electrical enclosure innovations. Empower your project with the right enclosure—engineered for safety, reliability, and long-term value.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services