A metal box may be any box, container, or another manufactured shape of metal enclosure used to house, store, and enclose various objects; in this instance, we specifically focus on a metal box as a container to house electrical components. These metal enclosures include numerous electrical cabinets, stainless steel, and aluminum enclosures. Moreover, such metal enclosures can be straightforward compared to other fabricated metal goods. Read More…

Since 1975, we have been doing precision sheet metal fabrication. Our expertise is in high production, high quality ISO 9000 Certified service. Dedicated manufacturing with on-time delivery. Electronic enclosures, chassis, frames, bracketry to extremely complex weldments and components.

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

EMCOR® Enclosures is a modular enclosure manufacturer and makes related component items as well. Our electronic equipment racks and enclosures feature an extensive selection of rack heights, widths, depths, and styles that target your specific design requirements. A variety of external and internal accessories are available to complete your design. Modified or custom designs are also available....

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

Buckeye ShapeForm manufactures electronic enclosures and electrical enclosures that take your company to the next level! Different types include desktop, handheld and rackmount. We will help you with the entire process, from selection, design and customization to finishing.

More Metal Box Manufacturers

However, metal enclosures are among the most significant and widely used types of fabricated metal products for industrial, commercial, and residential applications. The sizes of metal enclosures can range dramatically—from extremely large enclosures, such as those used for housing electrical substation equipment, to exceptionally small enclosures, such as those used for consumer light switch fixtures and compact electronics.

Metal boxes can be constructed in a wide range of shapes, including rounded, circular, cylindrical, and standard geometric designs like rectangles and squares. These versatile metal enclosures can be precisely stamped or pierced with holes to allow the secure passage of cords, wires, and cables—an essential feature for electrical equipment housing, data communication panels, and control panels.

Many metal boxes are equipped with robust doors or transparent glass panels, making it easy to inspect the enclosed machinery or electrical components without opening the box. This accessibility is critical for routine maintenance, safety checks, and troubleshooting in environments where uptime and reliability are paramount.

Manufacturing of Metal Boxes

The manufacturing of metal boxes and metal enclosures relies on advanced fabrication processes tailored to specific performance requirements and use cases. Metal stamping is one of the most common manufacturing techniques, enabling the transformation of flat sheet metal into both simple and highly complex shapes. Sheet metal fabrication allows for the creation of custom enclosure designs that meet precise dimensional tolerances and customer specifications.

Deep-drawn stamping is particularly advantageous for producing enclosures that need to be taller than they are wide, such as those that shield cylindrical tanks or house vertical electronic components. Deep-drawn stamping delivers seamless, durable, and high-precision enclosures, making it ideal for demanding industrial applications where structural integrity and longevity are critical. By minimizing the number of connected edges or seams, this process reduces the risk of component failure and eliminates the need for additional reinforcement at weak points.

For metal enclosures with more intricate or multi-stage designs, progressive die stamping enables continuous, high-volume manufacturing with complex shaping. The progressive die process incrementally modifies the metal, reducing material fatigue and increasing the strength of the finished enclosure. This is especially valuable in applications requiring repeated production consistency—such as electrical junction boxes, control panels, and custom OEM enclosures.

After the initial forming, metal enclosures often undergo additional processing to enhance their strength, durability, and environmental resistance. Common finishing techniques include annealing, hardening, powder coating, galvanizing, and other heat treatments. These steps prepare metal boxes for challenging environments, such as corrosive industrial settings, outdoor installations, and locations with extreme temperature fluctuations.

Are you looking for a custom metal enclosure for a unique application? Contact a metal box manufacturer to discuss sheet metal fabrication, CNC machining, and custom stamping options that fit your project requirements.

Types of Metal Boxes

There are several types of metal boxes, each engineered for specific electrical, mechanical, or environmental requirements. Understanding the differences between these enclosure types is essential for optimizing safety, code compliance, and performance in your installation.

Standard Rectangular Boxes

Standard rectangular boxes, often referred to as "single-gang" or "one-gang" boxes, are the most common electrical boxes found in residential and commercial wiring systems. These enclosures are used for single light fixture switches, power outlets, and receptacles. Many forms allow for modular expansion, enabling the connection of two or more boxes to accommodate multiple devices side by side. Removable sides make it easy to adapt configurations as electrical system requirements change.

2-Gang, 3-Gang, and 4-Gang Metal Boxes

Gangable metal boxes are designed for installations that require the side-by-side mounting of two, three, or four electrical devices—such as multiple switches, outlets, or dimmers. By removing the sides of standard rectangular boxes, these can be joined to create larger enclosures, ensuring flexibility and ease of wiring expansion. While galvanized steel is the material of choice for most gangable boxes due to its strength and fire resistance, some plastic alternatives exist but are less common in high-demand or code-sensitive environments.

Round Pan Metal Boxes

Round pan boxes, also known as "pancake" boxes, are shallow, circular enclosures frequently used for mounting lightweight ceiling or wall light fixtures. These boxes are ideal for applications where space is limited or where a low-profile installation is preferred. Some round metal pan boxes are rated for supporting ceiling fans, but it is critical to verify the product’s load rating and code compliance before installation. When planning your electrical wiring, always ensure that the number of conductors does not exceed the box’s rated fill capacity to maintain safety and meet NEC requirements.

Junction Boxes

Junction boxes are essential components in electrical systems, serving as secure enclosures for wire splices and distribution points. The most common junction box is a 4-inch square metal or high-impact plastic box, which provides ample room for wire connections involving multiple cables. Junction boxes are available in a range of sizes and materials to suit different voltage, amperage, and environmental protection needs. Selecting the right junction box is crucial for safe, code-compliant installations in commercial, industrial, and residential settings.

Other Specialty Metal Enclosures

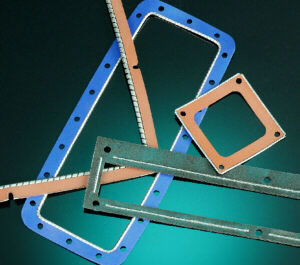

Beyond standard shapes and sizes, specialty metal boxes are available for unique applications, such as NEMA-rated weatherproof enclosures, explosion-proof boxes for hazardous environments, and custom instrument enclosures. These specialty boxes may feature advanced features such as gasketed seals, lockable doors, EMI/RFI shielding, and integrated climate controls.

Advantages of Metal Boxes

While metal boxes can be manufactured from a variety of metals—including aluminum, stainless steel, brass, and cast iron—steel enclosures are most frequently chosen for electrical and industrial use due to their superior protection, durability, and cost-effectiveness.

- Corrosion, Vermin, and Fire Resistance: Steel enclosures are highly resistant to corrosion, pests, and fire, making them ideal for both indoor and outdoor use in harsh or hazardous environments. They are capable of withstanding extreme heat, humidity, and exposure to chemicals, especially when properly coated or treated. The inclusion of weatherproof seals prevents moisture ingress, ensuring continued protection of sensitive electrical equipment.

- Environmental Sustainability: Steel is among the most recyclable materials in the world. Using steel enclosures contributes to environmentally friendly building practices and supports regulatory compliance for green building standards. Recycled steel reduces raw material usage and overall environmental impact, while maintaining high performance and strength.

- Long-Term Cost Savings: Although the initial cost of metal enclosures may be higher than plastic or composite alternatives, their extended lifespan, minimal maintenance requirements, and enhanced protection result in significant long-term savings. Steel enclosures are less susceptible to damage from impact, UV radiation, and fire, reducing the frequency and cost of replacements.

- Fire and Explosion Protection: Steel is a non-combustible material, making metal boxes inherently fire-resistant. This is especially important for industrial and commercial buildings, where electrical fires can have catastrophic consequences. For environments with explosion risks—such as chemical plants, refineries, or grain processing facilities—ATEX-rated and explosion-proof enclosures provide additional peace of mind and compliance with safety regulations.

- Customizability and Scalability: Metal boxes can be manufactured in a wide variety of shapes, sizes, and finishes to meet specific project requirements. Custom fabrication options include cutouts for connectors, ventilation louvres, mounting brackets, and integrated cable management systems.

Applications of Metal Boxes

Metal boxes and enclosures are indispensable across multiple industries and facility types. Their robust construction and protective features make them the enclosure of choice for a wide range of applications:

- Electrical Regulation and Distribution: Every building that uses electricity requires a secure metal electrical enclosure, such as a fuse box or circuit breaker panel. These boxes regulate power distribution, protect against overloads, and help prevent electrical fires. Outdoor electrical meter boxes are also commonly housed in weatherproof metal enclosures for durability and code compliance.

- Industrial Automation and Control: Metal enclosures are vital for protecting programmable logic controllers (PLCs), industrial computers, relays, sensors, and power supplies from dust, debris, moisture, and accidental impact. In manufacturing facilities, food processing plants, and energy production sites, these enclosures ensure reliable operation and safety.

- Data and Communications Infrastructure: Network cabinets, server racks, and telecom distribution boxes are often fabricated from steel or aluminum to shield sensitive electronics from electromagnetic interference (EMI) and physical damage. Properly designed metal enclosures help maintain network uptime and data integrity in commercial and institutional environments.

- Outdoor and Harsh Environment Installations: In outdoor settings, such as traffic control systems, remote monitoring stations, and security camera housings, metal enclosures offer weatherproof protection against rain, snow, UV exposure, and vandalism. Stainless steel and powder-coated aluminum are frequently used for maximum corrosion resistance.

- Hazardous Locations: For environments with flammable gases, dust, or potentially explosive atmospheres, specialized explosion-proof or ATEX-certified metal enclosures are mandated by safety codes. These enclosures are engineered to contain and isolate electrical sparks or faults, reducing the risk of ignition.

- Custom Instrumentation and OEM Equipment: Many manufacturers require custom metal boxes for enclosing proprietary electronics, sensors, or control systems. Custom fabricated enclosures can be tailored to include unique mounting patterns, thermal management features, and branding elements.

Use Cases: How to Select the Right Metal Box

Choosing the right metal enclosure or metal box is vital for ensuring safety, regulatory compliance, and reliable performance. Consider these key factors during your selection process:

- Environment: Will the enclosure be installed indoors, outdoors, or in a hazardous location? Select materials and finishes—such as galvanized steel, powder-coated aluminum, or stainless steel—that offer the appropriate level of protection.

- Enclosure Rating: Check for relevant certifications and ratings, including NEMA, UL, IP, or ATEX. These ratings determine suitability for moisture, dust, corrosion, explosion, and fire resistance.

- Dimensions and Internal Capacity: Ensure the box offers enough space for all wiring, components, and future expansion. Overcrowding can compromise safety and make maintenance difficult.

- Ease of Installation and Maintenance: Look for features such as pre-punched knockouts, removable covers, hinged doors, and ample cable management space to simplify installation and service.

- Aesthetic and Customization: For visible installations, consider the finish and appearance of the enclosure. Custom branding, color matching, and engraving may be available from your supplier.

Not sure which enclosure best fits your application? Contact a metal box supplier or use our comparison tools to find the optimal solution for your project.

Decision Factors: Comparing Metal, Plastic, and Composite Enclosures

When specifying an enclosure, it’s important to weigh the pros and cons of different materials. Here’s how metal boxes compare to alternative enclosure materials:

- Strength and Impact Resistance: Metal enclosures, especially steel and aluminum, provide superior impact resistance and structural strength compared to plastic or fiberglass alternatives.

- Fire Safety: Metal boxes are non-combustible and provide better fire containment than most non-metallic enclosures.

- EMI/RFI Shielding: Metal boxes block electromagnetic and radio frequency interference, protecting sensitive electronics and communications equipment.

- Corrosion Resistance: While plastics are inherently corrosion-resistant, metal enclosures can achieve similar performance with proper coatings or the use of stainless or galvanized steel.

- Weight: Plastic and composite boxes are lighter, which may be an advantage for portable or suspended installations; however, metal enclosures deliver unmatched durability for fixed, high-risk, or outdoor applications.

- Cost: Initial costs for metal enclosures can be higher, but their longevity and minimal maintenance often lower total cost of ownership over time.

Searching for the best enclosure for your needs? Compare metal and plastic enclosures by use case, rating, and budget to determine the right fit for your application.

Choosing the Proper Metal Box Supplier

To ensure the most positive outcome when purchasing a metal box from a reputable supplier, it is important to compare several companies using our comprehensive supplier directory. Each metal box supplier profile highlights their areas of expertise, manufacturing capabilities, and value-added services such as custom design, rapid prototyping, and finishing options. Use the integrated contact form to request additional information, obtain a quote, or discuss your unique requirements directly with the company.

Before making a purchasing decision, review each supplier’s website using our patented website previewer to understand their specialties, certifications (such as ISO 9001, UL, or NEMA compliance), and past project experience. Then, use our simple RFQ form to contact multiple metal box businesses simultaneously—saving time and ensuring you receive competitive pricing and technical guidance.

Ready to take the next step? Request a quote for your custom metal enclosure or download our buyer's guide for in-depth information on enclosure selection, standards, and industry best practices.

Frequently Asked Questions About Metal Boxes and Enclosures

- What is the best material for outdoor electrical enclosures? Stainless steel and powder-coated aluminum are top choices for outdoor use due to their corrosion resistance and durability. For extreme environments, NEMA 4X or IP66-rated enclosures are recommended.

- How do I determine the correct enclosure size? Calculate the total volume required for all components, wiring, and airflow, and ensure compliance with electrical code fill capacities. Allow extra space for future expansion or maintenance.

- Can metal boxes be customized with cutouts and branding? Yes. Most manufacturers offer custom cutouts, engraving, silk screening, and color matching. Provide detailed drawings or consult with your supplier for available customization options.

- Are metal boxes suitable for hazardous locations? Specialized metal enclosures certified to ATEX or UL explosion-proof standards are required for hazardous areas. Always check local codes and consult an expert for high-risk applications.

- What is the difference between NEMA and IP ratings? NEMA ratings are used primarily in North America, while IP (Ingress Protection) ratings are internationally recognized. Both measure protection against dust, water, and other environmental hazards. Choose the appropriate rating based on installation location and regulatory requirements.

Resources and Next Steps

For more information on metal enclosures, electrical boxes, and related products, explore our resources:

- Types of Metal Enclosures

- Manufacturing Processes for Metal Boxes

- Common Applications and Industries

- Metal vs. Plastic Enclosures: Comparison Guide

- Supplier Directory and RFQ Form

- Frequently Asked Questions

Still have questions or need a custom quote? Contact our team today or use our supplier directory to find experienced metal box manufacturers ready to support your next project.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services